The Molten Salt Technology Platform (MSTP) is a community of vendors, regulators, academics and national labs actively involved in the development of molten salt technologies. It showcases the UK’s current expertise in this field and demonstrates the feasibility of the technologies to meet net zero.

Molten Salt Technology has the potential to sit alongside other advanced nuclear technologies, not just from a safety, economic and environmental point of view but from a technological maturity perspective. This can be achieved through promotion of collaboration, education and dissemination of progress of molten salt developments through recognised bodies.

What is molten salt?

Salts are made up of positively and negatively charged atoms, which are referred to as ions. The bonds between ions are very strong, and as such they can only become liquid at very high temperatures. In the case of table salt, or sodium chloride, this occurs at 801°C. In this liquid state, the salt can now be considered molten. Each molten salt will exhibit different properties depending on its chemical structure.

General characteristics of molten salts include:

- Fluid behaviour

- Acting as solvents for a wide variety of materials

- Useful heat transfer characteristics

- Exhibiting high temperatures and low vapour pressure

- Good conductors of electricity

Where are molten salts used?

Molten salts can act as catalysts and decontamination reagents, have applications in non-ferrous metal production, fuel cells, coal gasification and hydrogen production. As molten salts can conduct electricity, they can also be used as battery materials. They are also important for heat transfer and thermal energy storage in solar arrays. Why is molten salt an important option for nuclear?

- Molten salts are robust to radiation – they suffer comparatively little damage when subjected to high levels of radiation.

- Their solvent properties can be used to dissolve nuclear fuel – uranium, plutonium or thorium – plus any fission, corrosion or activation products. This enables physical, chemical and electro-chemical processes to be undertaken.

- Their high heat capacity enables molten salts to act as a coolant, transferring large amounts of heat energy from a reactor core to a head exchanger. The heat can be used directly or converted to electricity. It also makes them ideal for energy storage applications – acting as a battery.

- The high temperatures and low vapour pressures result in greater efficiency.

- The ability for electrical conduction enables a current to be applied and dissolved waste separated from reusable components such as unused fuel.

Supporting net zero

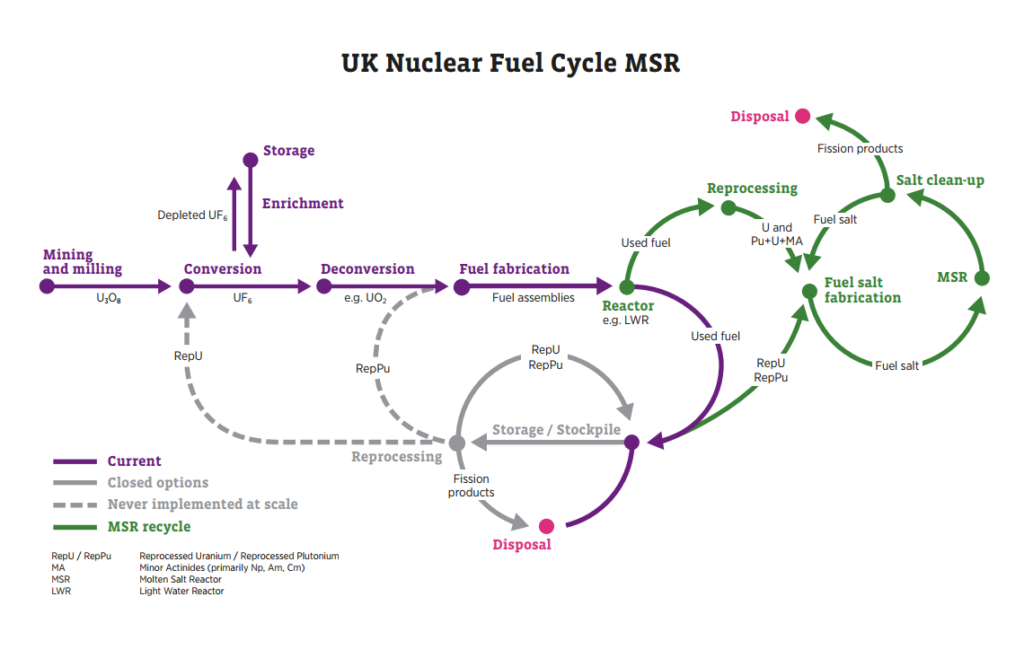

Molten salt technologies can be used to close the nuclear fuel cycle – meaning that used nuclear fuel can be cleaned and reused.

Molten salt reactors

Molten salt reactors are a broad range of technologies, in which the molten salt may be used as a combined fuel and coolant – or as a coolant only. The reactor can be designed for energy production or ‘waste burning’ – reducing the content of long-lived radioactive isotopes. Molten salt reactors can operate with different fuels, primarily uranium or thorium, and different salts in different modes – thermal or fast spectrum. In thermal spectrum mode, the neutrons are slowed by a moderator, in a fast spectrum mode, they are not. The speed of the neutrons determines how they interact with elements in the reactor.

Advantages include:

- Very flexible designs – big or small

- Some designs can eliminate nuclear waste

- Operating at high temperature for efficient electricity generation, hydrogen production and district heating

- Passive safety:

- As the salt gets hotter it expands and the nuclear reaction slows down

- Some reactors are designed with a ‘freeze plug’. If the temperature rises too high, this transfers the salt into a separate containment vessel

- Reactor designs operate at lower pressures than conventional reactors, meaning there cannot be an explosion due to vessel pressurisation

- Lower operating pressure reduces the need for thick, heavy vessel manufacture, lowering construction cost

- Fissile fuel is intimately mixed with the salt, increasing resistance to proliferation

Pyrochemical processing

In a molten salt reactor, the fuel is mixed with the molten salt, in contrast to existing reactor technologies that use solid fuel. Several sites across the world, eg, Sellafield in the UK, use aqueous reprocessing to separate out the reusable components of the fuel from the waste. Advanced forms of aqueous reprocessing are being developed. An alternative and complementary option is pyrochemical processing. The molten salt is more robust to high levels of radiation than the organic solvents in aqueous reprocessing. In fact, molten salt reactors may operate a pyrochemical process to clean up their salt during operation.

The basics concepts of pyrochemical processing are shown in this video below:

Energy transfer and storage

Molten salts are commonly used for thermal energy storage. Current applications are in concentrating solar power. Excess heat that is not used for electricity generation is diverted to the molten salt, which is then stored in an insulated tank. After sunset, this thermal energy can be used to produce steam and generate electricity when the sun is no longer providing energy to the plant. This thermal energy storage capacity can also be used to smooth electricity production throughout the day and mitigate the variability associated with solar PV technologies. Molten salts are typically nitrates or carbonates, but there is increased interest in the use of chlorides and more advanced materials. In a nuclear context, since nuclear provides a continuous source of power, molten salt energy storage can be used as a ‘buffer’ between times of peak and low power demand.

Molten Salt Advisory Group (MSAG)

The MSTP has representation from MSAG. MSAG is a community of academics who can provide the UK government with an independent view on molten salt technologies. In order not to compromise their independence, a representative joins MSTP meetings to provide an update on any developments in academia and provides feedback from the MSTP community.

MSTP Portal

Members of MSTP can see copies of meeting agendas and minutes at this limited-access site. It may also be used to share documents as part of ongoing MSTP projects. If you are interested in joining the MSTP community, please get in touch though Mike.J.Edmondson@UKNNL.com